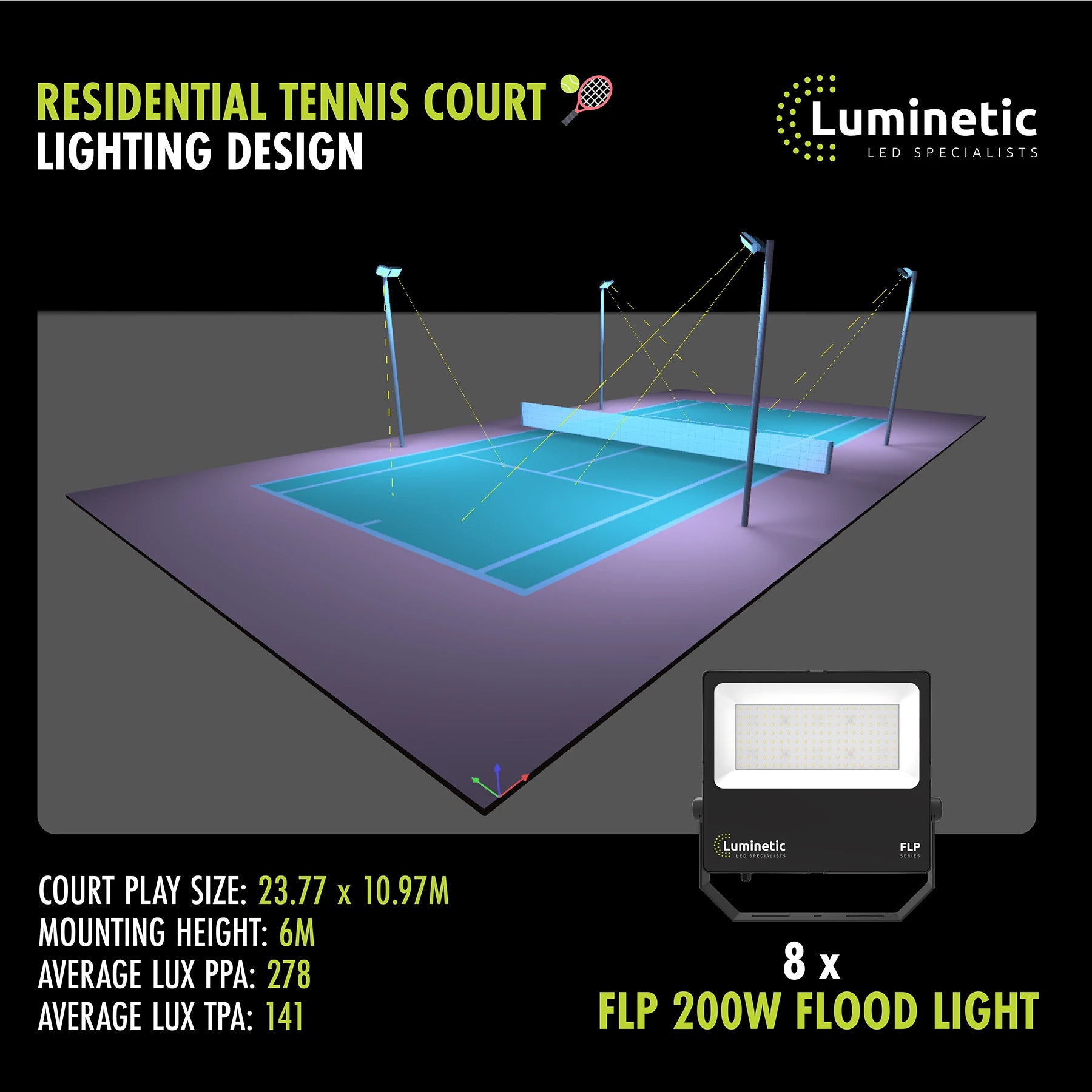

This industrial operator in Wangara, WA has just upgraded their truck loading area lighting—and the difference is clear.

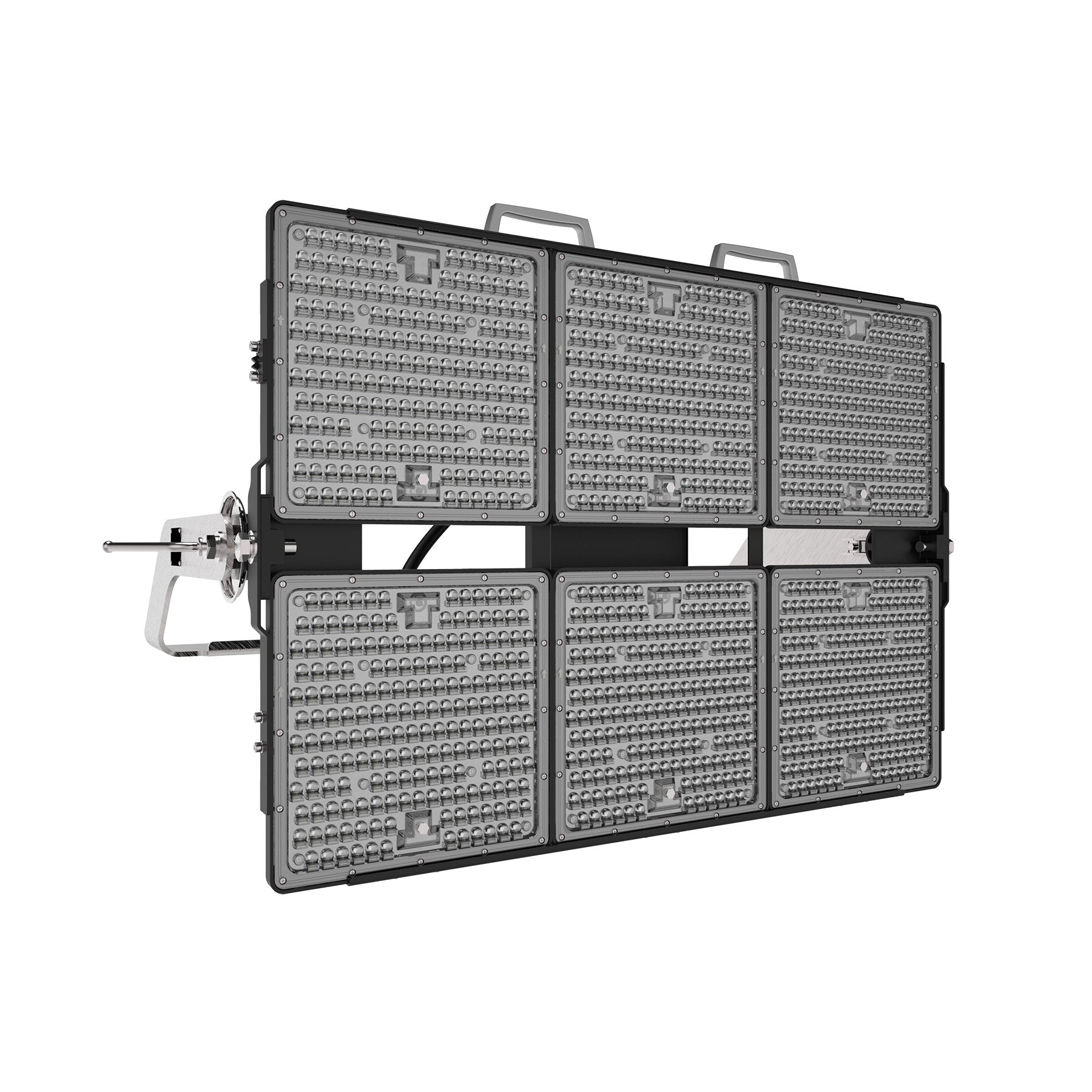

The site has replaced eight aging 2000W metal halide fittings with four new 1200W LED HMX fittings.

By halving the number of fittings, the operator has shrunk their lighting power requirements.

Total power consumption has dropped from 16,000W (plus 10% ballast loss) to 4,800W.

🌳 That's a 70% decrease!

This kind of decrease reflects in your future power bills, too. It also means your operations produce less associated emissions - always a good thing.

There's more good news ahead for their maintenance team, too.

Metal halide lamps have a poor lifetime, around 5,000 to 10,000 hours.

If you still have high mast metal halide light fittings onsite, you're probably spending time and money, year after year, hiring an EWP to swap out globes 🤦♂️

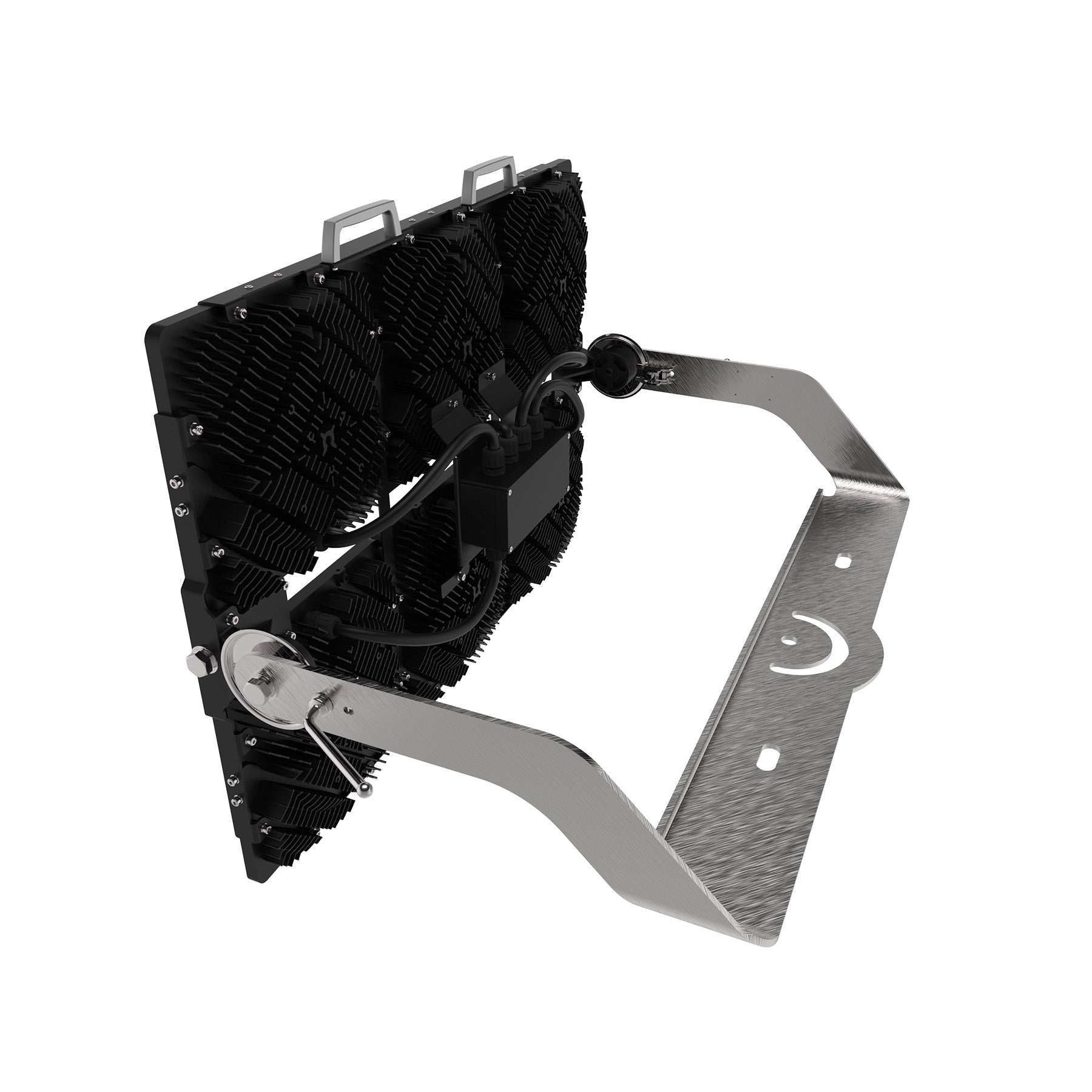

Compare this to our HMX fittings, which are rated to >60,000 hours at L70.

That means that:

even after seven years straight of CONTINUOUS 24/7 operation, they'll still retain 70% efficiency.

🛠 There's no scheduled maintenance requirements. No more lamp changes. No more hiring EWP's.

Site operators are already enjoying the higher quality of light from these LED fittings.

Also new is the fact that they switch on instantly - no more warm-up required.

You get a lot when you upgrade to LED!